- Home

- About us

- Products

- Lab fermenter(SS316, 5L-50L)

- Industry fermenter(1KL-400KL)

- Mammalian cell bioreactor(5L-10KL)

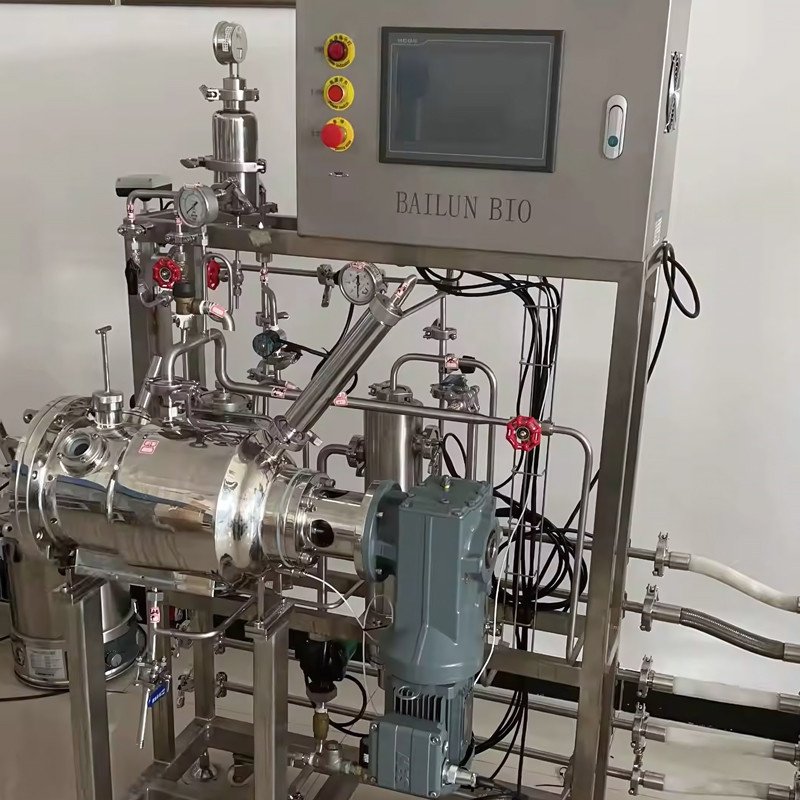

- Lab Fermenter Bioreactor Industrial Stainless Steel Fermenter

- Vaccine Fermenter(GMP) Fermentation Equipment stainless Steel Bioreactor

- Mini Lab Glass Fermenter Magnetic Mixing Cell Culture Fermenter Bioreactor

- CIP Station Automatic Bioreactor Fermenter

- Faqs

- News

- Certificate

- Contact us

Insights on Veterinary Vaccine Manufacturers in China and Their Use of Fermenters and Bioreactors

Question 1: What are the key considerations for veterinary vaccine manufacturers in China when choosing fermenters and bioreactors?

The main considerations include the capacity and scalability of the equipment to meet production demands, the ability to maintain precise control over parameters such as temperature, pH, and dissolved oxygen for optimal vaccine quality, and the compatibility with the specific vaccine production processes and microbial strains used.

Question 2: How do Chinese veterinary vaccine manufacturers ensure the quality and safety of vaccines produced using fermenters and bioreactors?

They adhere to strict quality control measures throughout the production process. This includes regular equipment maintenance and calibration, validation of the production processes, rigorous testing of raw materials and final products, and implementation of good manufacturing practices (GMP) to prevent contamination and ensure consistency.

Question 3: Are there any specific regulations or standards in China for the operation of fermenters and bioreactors in veterinary vaccine production?

Yes, there are comprehensive regulatory frameworks and standards set by the relevant authorities. These regulations cover aspects such as equipment design, operation procedures, sterilization methods, and quality control to ensure the safety and efficacy of the produced vaccines.

Question 4: How do advancements in fermenter and bioreactor technology impact the veterinary vaccine industry in China?

Advancements lead to increased production efficiency, improved vaccine quality, and the ability to develop more complex and effective vaccines. New technologies also allow for better control of process parameters, reduced production costs, and enhanced scalability to meet market demands.

Question 5: Can you provide examples of successful veterinary vaccine products from Chinese manufacturers that utilize advanced fermenters and bioreactors?

Some well-known examples include vaccines for common diseases in livestock such as foot-and-mouth disease and avian influenza. These vaccines have demonstrated high efficacy and have contributed to the prevention and control of diseases in the animal population.

Question 6: How do Chinese manufacturers train their staff to operate and maintain fermenters and bioreactors effectively?

They provide comprehensive training programs that include theoretical knowledge about the equipment and hands-on practical sessions. Staff also undergo regular refresher courses to stay updated with the latest technologies and operational best practices.

Question 7: What challenges do Chinese veterinary vaccine manufacturers face regarding the import of fermenters and bioreactors?

Challenges may include import regulations, compatibility with local infrastructure and utilities, and the need for technical support and spare parts availability from foreign suppliers.

Question 8: How do Chinese manufacturers balance the cost of investing in new fermenters and bioreactors with the potential benefits in vaccine production?

They conduct detailed cost-benefit analyses considering factors such as increased productivity, improved product quality, market demand, and the potential for long-term savings in production and quality control.

Question 9: Do Chinese veterinary vaccine manufacturers collaborate with international counterparts in the field of fermenter and bioreactor technology?

Yes, collaborations occur through joint research projects, technology exchanges, and partnerships to share knowledge and expertise in optimizing vaccine production processes.

Question 10: What is the future outlook for the use of fermenters and bioreactors in the Chinese veterinary vaccine manufacturing sector?

The outlook is promising, with continued investment in research and development, adoption of more advanced technologies, and an increased focus on sustainable and efficient production methods to meet the growing demand for high-quality veterinary vaccines both domestically and internationally.