- Home

- About us

- Products

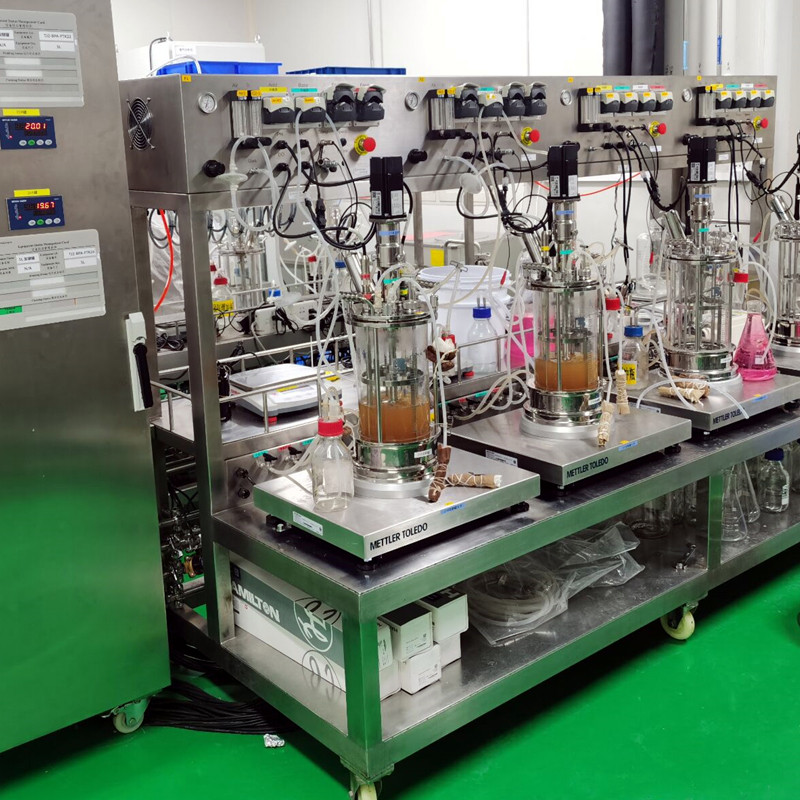

- Lab fermenter(SS316, 5L-50L)

- Industry fermenter(1KL-400KL)

- Mammalian cell bioreactor(5L-10KL)

- Lab Fermenter Bioreactor Industrial Stainless Steel Fermenter

- Vaccine Fermenter(GMP) Fermentation Equipment stainless Steel Bioreactor

- Mini Lab Glass Fermenter Magnetic Mixing Cell Culture Fermenter Bioreactor

- CIP Station Automatic Bioreactor Fermenter

- Faqs

- News

- Certificate

- Contact us

Insights into the 20-Gallon Glass Mixing Tank Fermenter

Question 1: What is a 20-gallon glass mixing tank fermenter?

A 20-gallon glass mixing tank fermenter is a specialized container designed for the process of fermentation and mixing. It is made of glass and has a capacity of 20 gallons, providing a controlled environment for various biological or chemical reactions.

Question 2: What are the advantages of using a glass material for the tank?

Glass offers excellent visibility, allowing for easy monitoring of the fermentation process. It is chemically inert, meaning it doesn't react with the substances inside. It is also easy to clean and sterilize, ensuring a contamination-free environment.

Question 3: How is the mixing achieved in this fermenter?

Mixing can be accomplished through various means such as mechanical stirrers, magnetic stir bars, or by the injection of gases to create circulation within the tank.

Question 4: What types of substances can be processed in this fermenter?

It can be used for a wide range of applications, including the fermentation of microorganisms to produce enzymes, alcohols, or other metabolites. It can also be used for the mixing and reaction of chemical solutions.

Question 5: How is the temperature controlled in the 20-gallon glass fermenter?

Temperature control can be achieved through external jackets filled with heating or cooling fluids, or by using immersion heaters or coolers.

Question 6: What safety precautions should be taken when using this fermenter?

Care must be taken to handle the glass tank with care to avoid breakage. Pressure and temperature limits should be adhered to prevent any damage. Also, proper ventilation is necessary if volatile substances are being processed.

Question 7: Can this fermenter be used for both batch and continuous processes?

Yes, it can be configured and operated for both batch and continuous fermentation or mixing processes, depending on the specific requirements of the application.

Question 8: How often does the tank need to be cleaned and maintained?

The frequency of cleaning and maintenance depends on the nature of the substances processed, but typically, it should be cleaned thoroughly after each use and undergo regular inspections for any signs of damage or wear.

Question 9: What kind of sensors and monitoring equipment can be installed with this fermenter?

Common sensors include temperature sensors, pH sensors, dissolved oxygen sensors, and pressure sensors. Monitoring equipment like data loggers and control systems can be integrated to keep track of the process parameters.

Question 10: Is it possible to scale up the process from a 20-gallon glass fermenter to a larger size?

Yes, but scaling up requires careful consideration of factors such as mixing efficiency, heat transfer, and mass transfer, which may differ in larger vessels.