- Home

- About us

- Products

- Lab fermenter(SS316, 5L-50L)

- Industry fermenter(1KL-400KL)

- Mammalian cell bioreactor(5L-10KL)

- Lab Fermenter Bioreactor Industrial Stainless Steel Fermenter

- Vaccine Fermenter(GMP) Fermentation Equipment stainless Steel Bioreactor

- Mini Lab Glass Fermenter Magnetic Mixing Cell Culture Fermenter Bioreactor

- CIP Station Automatic Bioreactor Fermenter

- Faqs

- News

- Certificate

- Contact us

Bioreactors for Bacteria: The Role of Stainless Steel Fermenters

time2024/07/21

- Bioreactors for Bacteria: The Role of Stainless Steel Fermenters

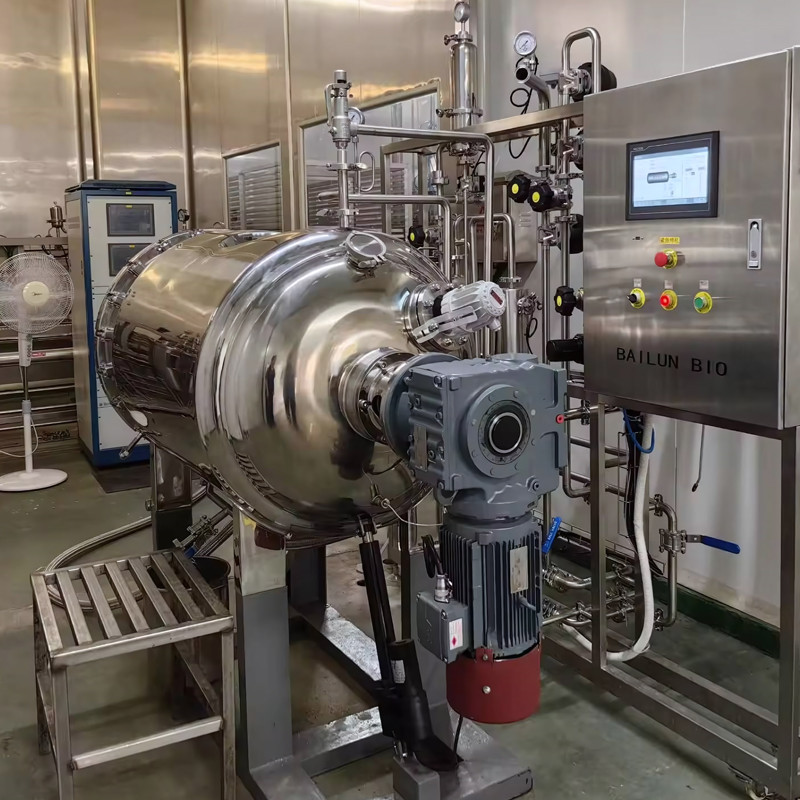

In the field of microbiology and biotechnology, bioreactors have become indispensable tools for the cultivation and study of bacteria. Among the various types of bioreactors, stainless steel fermenters stand out for their numerous advantages and crucial role in facilitating efficient and controlled bacterial growth processes. This article delves into the world of bioreactors dedicated to bacteria, with a particular focus on the significance and characteristics of stainless steel fermenters.

Stainless steel fermenters offer a combination of durability, resistance to corrosion, and ease of sterilization that makes them highly suitable for bacterial cultures. The choice of stainless steel as the construction material ensures the longevity and integrity of the fermenter, allowing it to withstand the rigors of repeated use and harsh operating conditions.

The design of a stainless steel fermenter Bioreactor is meticulously engineered to provide an optimal environment for bacterial growth. The vessel is typically equipped with systems for precise control of parameters such as temperature, pH, dissolved oxygen, and agitation. These control mechanisms are essential for maintaining the delicate balance of conditions that bacteria require for vigorous growth and metabolic activity.

Temperature regulation is critical, as different bacterial species have specific temperature preferences for optimal growth and reproduction. Stainless steel fermenters are often outfitted with heating and cooling jackets or coils that enable accurate and rapid adjustments to maintain the desired temperature range. Similarly, pH control is achieved through the addition of acids or bases, and the fermenter is fitted with pH sensors to monitor and maintain the pH within the ideal range for the particular bacterial strain.

Dissolved oxygen is another vital factor, especially for aerobic bacteria. The design of the agitation and aeration systems in the stainless steel fermenter ensures a continuous supply of oxygen to support bacterial respiration. Efficient mixing also prevents the formation of gradients within the culture medium, ensuring that all bacteria have access to uniform conditions and nutrients.

The size and shape of the stainless steel fermenter are determined based on the scale of the operation and the specific requirements of the bacterial culture. For laboratory-scale studies, smaller fermenters may suffice, while industrial-scale production often requires large-capacity vessels to meet the demand for high-volume bacterial growth and product formation.

In addition to the physical design, the surface properties of the stainless steel within the fermenter can also influence bacterial behavior. Specialized coatings or surface treatments may be applied to enhance cell adhesion or prevent unwanted interactions that could affect the growth and productivity of the bacteria.

The use of stainless steel fermenters is not limited to a specific type of bacterial culture. They can be adapted for a wide range of applications, from the production of antibiotics and enzymes to the cultivation of probiotic bacteria for food and health products. The flexibility and versatility of these Industrial fermenters make them valuable assets in various sectors of biotechnology.

In the context of research, stainless steel fermenters provide a controlled and reproducible environment that enables scientists to study bacterial physiology, genetics, and metabolism in detail. By manipulating the parameters within the fermenter, researchers can gain insights into how bacteria respond to different stimuli and optimize the conditions for desired outcomes.

In industrial settings, the scalability and reliability of stainless steel fermenters are key factors in achieving consistent and efficient production. The ability to precisely control and monitor the fermentation process helps ensure the quality and purity of the final products, meeting the strict standards of the industry.

However, the operation and maintenance of stainless steel fermenters require careful attention. Regular cleaning and sterilization are essential to prevent contamination and the build-up of residues that could interfere with the performance of the fermenter and the quality of the bacterial culture. Additionally, proper calibration and monitoring of the control systems are necessary to ensure accurate and reliable operation.

Looking ahead, the field of bioreactors for bacteria is likely to witness further advancements. New developments in materials science may lead to the creation of even more advanced stainless steel alloys or alternative materials with enhanced properties. Integration with technologies such as sensors, artificial intelligence, and automated control systems is expected to provide even greater precision and optimization of the fermentation process.

In conclusion, stainless steel fermenters play a central role in the realm of bioreactors for bacteria. Their ability to provide a controlled, scalable, and reliable environment for bacterial growth makes them indispensable in both research and industrial applications.

Continued innovation and improvement in the design and functionality of these fermenters will undoubtedly contribute to the advancement of microbiology and biotechnology, opening up new possibilities for the development of novel products and processes.