- Home

- About us

- Products

- Lab fermenter(SS316, 5L-50L)

- Industry fermenter(1KL-400KL)

- Mammalian cell bioreactor(5L-10KL)

- Lab Fermenter Bioreactor Industrial Stainless Steel Fermenter

- Vaccine Fermenter(GMP) Fermentation Equipment stainless Steel Bioreactor

- Mini Lab Glass Fermenter Magnetic Mixing Cell Culture Fermenter Bioreactor

- CIP Station Automatic Bioreactor Fermenter

- Faqs

- News

- Certificate

- Contact us

Mini Bench-top Cell Culture Bioreactor: Enabling Advances in Cell-Based Research and Biotechnology

time2024/07/29

- Mini Bench-top Cell Culture Bioreactor: Enabling Advances in Cell-Based Research and Biotechnology

In the dynamic field of cell biology and biotechnology, the mini bench-top cell culture bioreactor has emerged as a powerful tool, revolutionizing the way we conduct experiments and drive innovation. This article aims to provide an in-depth exploration of the mini bench-top cell culture bioreactor, covering its design, functionality, applications, and the significant impact it has on various aspects of scientific research and industrial processes.

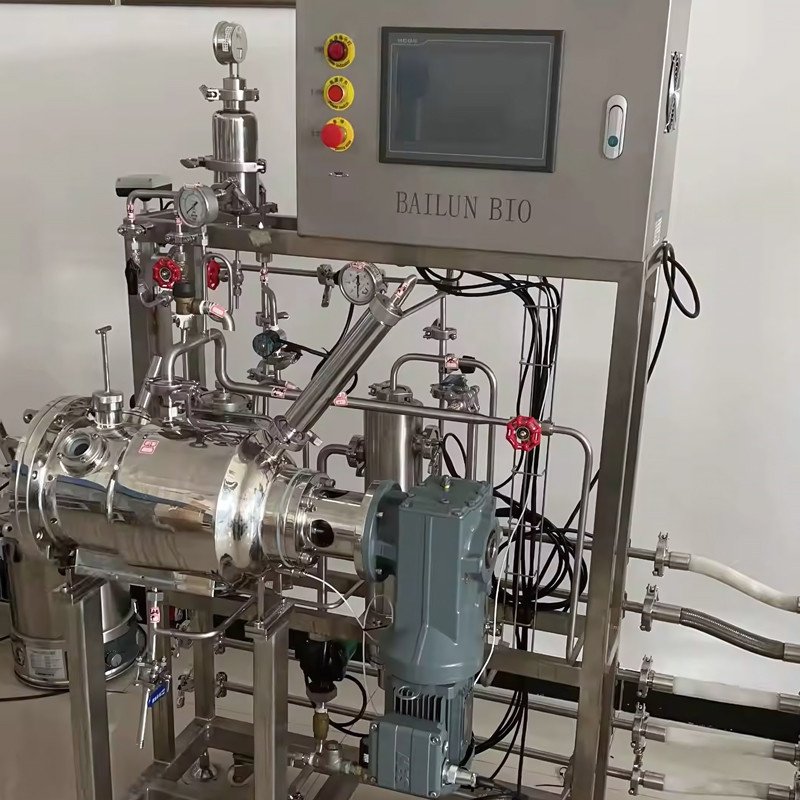

The design of the mini bench-top cell culture bioreactor is a result of meticulous engineering and consideration of the specific needs of cell culture. These bioreactors are typically compact in size, making them suitable for placement on a laboratory bench without occupying excessive space. Despite their small footprint, they are equipped with sophisticated components that ensure optimal cell growth and functionality.

The bioreactor vessel is often made of materials that are biocompatible and resistant to chemical interactions, providing a safe and stable environment for the cells. The inner surface is treated to prevent cell adhesion and promote uniform cell distribution. The design also incorporates features for efficient gas exchange, allowing for the proper supply of oxygen and removal of carbon dioxide.

Temperature control is a crucial aspect of the design. Mini bench-top bioreactors are equipped with precise heating and cooling systems that can maintain the desired temperature within a narrow range. This is essential as even slight variations in temperature can have a significant impact on cell metabolism and viability.

pH regulation is another critical component. Sensors and control mechanisms are in place to monitor and adjust the pH of the culture medium, ensuring that it remains within the optimal range for cell growth and function.

Agitation or mixing is achieved through carefully designed mechanisms to ensure uniform distribution of nutrients and gases throughout the culture volume. This helps prevent the formation of gradients and ensures that all cells have access to the necessary substances for growth and proliferation.

The functionality of the mini bench-top cell culture bioreactor lies in its ability to provide a controlled and reproducible environment for cell cultures. The ability to precisely monitor and control parameters such as temperature, pH, dissolved oxygen, and nutrient concentrations allows for a better understanding of cell behavior and responses under different conditions.

One of the significant advantages of these bioreactors is the real-time monitoring capabilities. Integrated sensors can continuously measure various parameters and provide instant feedback, allowing researchers to make timely adjustments and optimizations to the culture conditions. This real-time data collection and analysis are invaluable in studying cell kinetics, metabolism, and growth patterns.

The mini bench-top cell culture bioreactor also offers the possibility of performing multiple experiments simultaneously. This enables researchers to compare different conditions, cell lines, or treatment regimens in a parallel manner, increasing the efficiency and productivity of the research.

The applications of the mini bench-top Animal Cell bioreactor are diverse and far-reaching. In the field of drug discovery and development, it plays a crucial role in screening potential drug candidates. By culturing cells in a controlled environment, researchers can assess the efficacy and toxicity of drugs, providing valuable insights into their potential therapeutic effects.

In stem cell research, the bioreactor provides an ideal platform for studying stem cell differentiation and expansion. The controlled conditions allow for precise manipulation of factors that influence stem cell fate, opening up possibilities for regenerative medicine and tissue engineering applications.

The bioreactor is also utilized in the production of biologics, such as monoclonal antibodies and recombinant proteins. The ability to maintain consistent culture conditions leads to higher product yields and quality, which is essential for meeting the demands of the biopharmaceutical industry.

In cancer research, it helps in understanding the mechanisms of tumor growth and metastasis. By culturing cancer cells in a bioreactor, researchers can simulate the tumor microenvironment and study the responses of cancer cells to various treatments.

However, the use of mini bench-top cell culture bioreactors is not without challenges. Maintaining sterility is of paramount importance, as any contamination can compromise the entire experiment. The small size of the bioreactor can make sterilization and cleaning procedures more challenging, requiring meticulous attention to detail.

Calibration and validation of the sensors and control systems are crucial to ensure the accuracy and reliability of the data obtained. Additionally, optimizing the culture medium and operating parameters for specific cell types and applications often requires extensive experimentation and optimization.

Despite these challenges, the mini bench-top cell culture bioreactor has undoubtedly transformed the landscape of cell-based research and biotechnology. Its ability to provide a controlled, reproducible, and efficient platform for cell culture has opened up new avenues for discovery and innovation.

Looking forward, the continued development and improvement of mini bench-top cell culture bioreactors are expected. Advances in sensor technology, materials science, and control algorithms will likely lead to even more precise and sophisticated systems. The integration of artificial intelligence and machine learning could enable predictive modeling and optimization of cell culture processes, further enhancing the capabilities of these bioreactors.

In conclusion, the mini bench-top cell culture Stirred Tank bioreactor has emerged as a vital tool in the arsenal of modern cell biologists and biotechnologists. Its ability to provide a controlled and reproducible environment for cell cultures has paved the way for significant advancements in various fields, from drug discovery to regenerative medicine.

As technology progresses, the role of these bioreactors is likely to become even more prominent, driving further breakthroughs and shaping the future of biomedical research and industrial applications.