- Home

- About us

- Products

- Lab fermenter(SS316, 5L-50L)

- Industry fermenter(1KL-400KL)

- Mammalian cell bioreactor(5L-10KL)

- Lab Fermenter Bioreactor Industrial Stainless Steel Fermenter

- Vaccine Fermenter(GMP) Fermentation Equipment stainless Steel Bioreactor

- Mini Lab Glass Fermenter Magnetic Mixing Cell Culture Fermenter Bioreactor

- CIP Station Automatic Bioreactor Fermenter

- Faqs

- News

- Certificate

- Contact us

Overview | Empowering Biological Manufacturing with Artificial Intelligence

time2024/11/11

- Biomanufacturing is an advanced technology with great potential for constructing highly biomimetic three-dimensional human organs in vitro.

This technology will help solve the problems of immune rejection and organ donor shortage in organ transplantation, assist doctors in developing personalized treatment plans for clinical patients, and replace animal experiments. Biomanufacturing typically involves interdisciplinary applications of biology, materials science, mechanical engineering, and medicine to generate large amounts of data and correlations that require processing and analysis.

Schematic diagram of artificial intelligence integrated biomanufacturing. (A) A simple biomanufacturing flowchart consisting of three steps: preparation process, manufacturing process, evaluation and application. Growth factors (GFs) are a class of bioactive proteins or peptides that can regulate cell growth, proliferation, differentiation and survival. They are common ingredients in bio ink formulations. (B) Medical image preprocessing and feature extraction. (C) Model design and optimization. (D) Cell sorting and quality control.

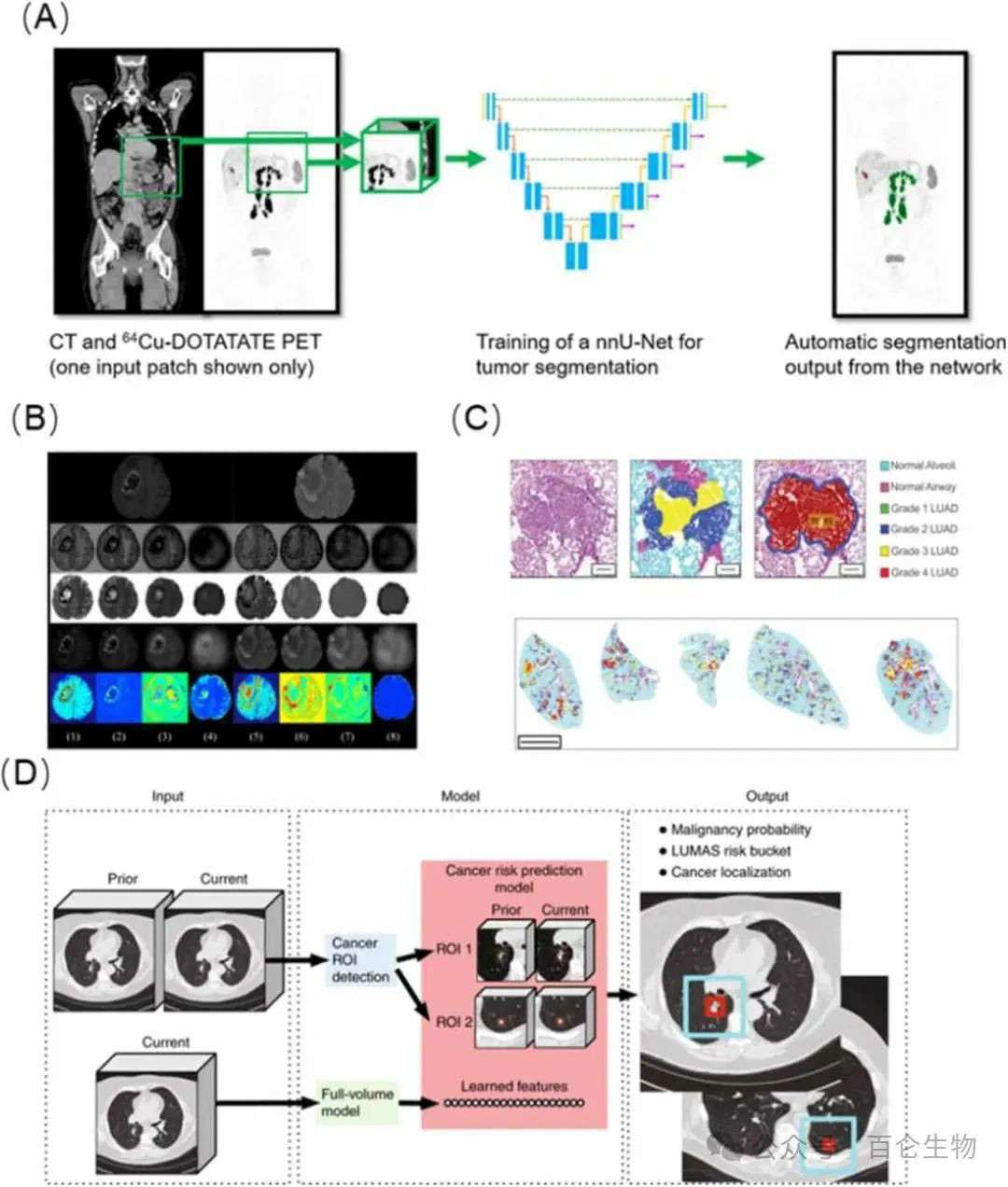

Medical image processing based on artificial intelligence. (A) Convolutional neural networks for whole tumor segmentation of neuroendocrine tumors aim to depict regions of interest with specific meanings in medical images and extract relevant features. This provides a reliable basis for clinical diagnosis and pathological research, helping doctors make more accurate diagnoses. The typical process of AI algorithm recognition and detection of medical diagnostic images is shown in the figure.

Structural design and cell sorting based on artificial intelligence. (A) Applying machine learning models that do not require prior data to bone scaffold design has improved the performance and repair capability of the scaffold. (B) Study on the influence of microfluidic chip structure on fluid dynamics. Three different flow carving devices alter the same inlet fluid flow schematic diagram (left), and research on artificial intelligence based micro column sequence prediction in the flow channel (right).

Optimization of biological links and manufacturing parameters based on artificial intelligence. (A) The flowchart of artificial intelligence in ink research; Artificial intelligence can evaluate the printability of ink or predict ink culture by analyzing ink performance tests and identifying and analyzing printing structures.

Real time monitoring of manufacturing processes based on artificial intelligence. (A) Squeeze bioprinting and EHDP real-time monitoring system, integrating AI for real-time monitoring of printed structures, including structural defects, abnormalities, and printability indicators.

Detection of biomanufacturing models based on artificial intelligence. (A) The trained AI model can predict the fluorescence labeling of unlabeled cells and analyze gene expression and other states. (B) AI can help analyze key indicators of tumor spheroid models and evaluate their migration and invasion abilities.