- Home

- About us

- Products

- Lab fermenter(SS316, 5L-50L)

- Industry fermenter(1KL-400KL)

- Mammalian cell bioreactor(5L-10KL)

- Lab Fermenter Bioreactor Industrial Stainless Steel Fermenter

- Vaccine Fermenter(GMP) Fermentation Equipment stainless Steel Bioreactor

- Mini Lab Glass Fermenter Magnetic Mixing Cell Culture Fermenter Bioreactor

- CIP Station Automatic Bioreactor Fermenter

- Faqs

- News

- Certificate

- Contact us

Will high-throughput process development reshape biopharmaceuticals?

time2025/02/06

- High throughput process development (HTPD) has emerged and its importance is constantly increasing in the industry.

In the biopharmaceutical industry, traditional process development methods face problems of low productivity, high costs, and difficulty in meeting the growing demand for candidate drug development and regulatory requirements.

High throughput upstream process development

Plan and time: If 5-10 parameters are studied in the development of microbial fermentation process, it usually takes 4 weeks; The process of mammalian cell culture research for 10 days will increase the time by 2-3 times; The typical cell culture process for developing classic bioreactors takes 3-4 months.

Existing systems and features

Small shaking flasks, microtiter plates, rotary tubes, and microfluidics: 24 well, 48 well, and 96 well formats are common and can be used for batch screening, clone screening, and cell culture medium screening of low VCD. However, microtiter plates are usually only used as screening tools and provide limited data.

Microfluidic bioreactor: With a small working volume (5-700 mL), it can be assembled in parallel to provide high experimental throughput and has successfully optimized antibody production.

However, the oxygen transfer rate is low (which can be improved by introducing a peristaltic oxygenation mixer) and lacks the ability to study complex feeding strategies. The monitoring of pH and DO is usually accomplished through optical sensors.

Different model systems are suitable for different types of research, each with its own advantages and disadvantages. For example, the microtiter plate format can be used for various studies but has limitations. Small bioreactor systems as development platforms have many advantages.

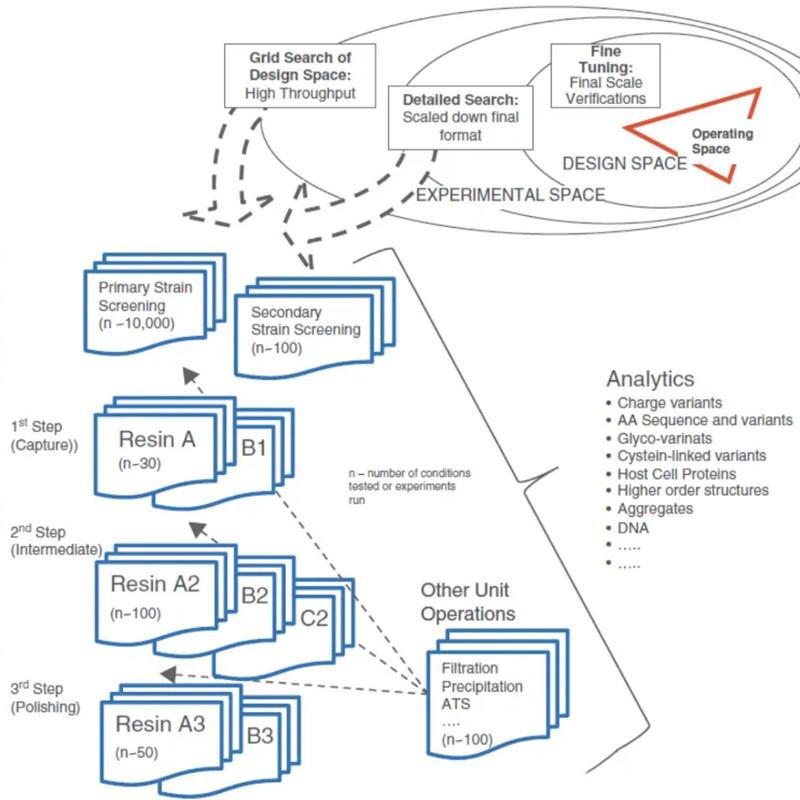

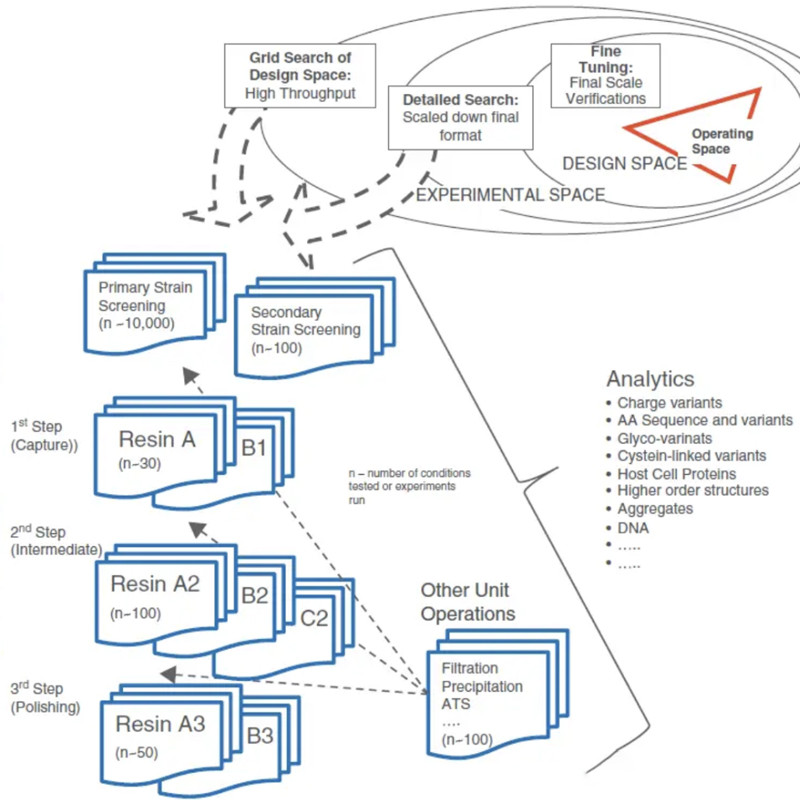

High throughput downstream process development

Key points of model system design: The scaled down model of downstream purification steps should be able to represent the operation of large-scale equipment and provide relevant data, among which the reduction of chromatography is the most challenging.

High throughput technology and applications

Format and Application: Currently, there are three formats available: micro titration filter plate, pre packaged pipette tip, and pre packaged mini column. Different formats are suitable for different studies.

If the methods based on plates and tips are used to study semi equilibrium conditions, microcolumns can be used for various chromatographic studies. By modifying the laboratory multi-channel liquid processor, higher experimental flux of microcolumns can be achieved;

The pre filled pipette tip allows the sample to come into contact with the chromatographic resin, and its convection conditions are similar to a packed bed; The technology based on the principle of batch adsorption and the combination of microtiter plate format can be used for various studies, and the manual operation process is simple.

Problems and Improvements in High Throughput Research

High throughput workflow will introduce bottlenecks in automation, analysis, and data evaluation, with heavy analysis burden and limitations on the types of systems used by upstream operations.

The small sample size will affect subsequent quality attribute analysis, and the identification of key process parameters will depend on analysis and testing results.

The development of monoclonal antibody technology requires multiple analytical methods to determine purity and impurities.

Some techniques have been converted to HTS format, but faster and more sensitive high-throughput analytical techniques still need to be developed, such as improving aggregate quantification methods or optimizing deployment strategies for existing analytical techniques.

The impact of high-throughput methods on process development efficiency and overall process knowledge has been significant and will become increasingly important.

With the maturity of technologies and automation that support high-throughput analysis and process development, it is expected that systems used for high-throughput process development will continue to develop in the coming years.

This includes faster and more sensitive high-throughput analysis techniques, as well as standardized data analysis platforms.